Hey there, future-proof professionals and aspiring electricians! Ever felt that unique blend of excitement and a touch of trepidation when you think about tackling a hands-on electrical challenge?

I totally get it. The world of electrotechnology is absolutely electrifying right now, with advancements in smart infrastructure, renewable energy systems, and industrial automation happening at lightning speed.

This means the demand for skilled pros who can not only understand these complex systems but also confidently install and operate them is soaring. Passing those practical certification exams isn’t just about ticking a box; it’s your golden ticket to a thriving career in a dynamic field.

From my own journey, I quickly learned that mastering equipment installation and operation is the cornerstone of success, turning potential exam anxiety into pure confidence.

If you’re ready to switch on your career and bypass those common practical exam pitfalls, you’re in the right place. Let’s power through the details and learn exactly how to ace your electrotechnology practical exams!

Decoding the Electrotechnology Practical Exam Blueprint

Stepping into the practical exam room can feel a bit like walking onto a stage – all eyes are on you, and every move matters. From my own experience, the biggest hurdle often isn’t the difficulty of the tasks themselves, but rather understanding what the examiners are truly looking for. It’s not just about getting the wiring right; it’s about following protocol, demonstrating sound judgment, and showcasing your understanding of why certain steps are critical. I’ve seen so many talented folks stumble because they overlooked a minor procedural detail or rushed through a safety check, not realizing these are weighted just as heavily as the final circuit functionality. Examiners are assessing your holistic competence, which includes your ability to interpret schematics, select appropriate tools, execute tasks precisely, and adhere to industry standards. Think of it as a meticulously choreographed dance where every step is scrutinized. Knowing this upfront totally transforms your preparation, guiding you to focus not just on ‘what to do’ but ‘how to do it’ with an examiner’s eye.

Navigating Common Exam Scenarios

You’ll likely encounter a mix of installation, troubleshooting, and operational tasks. I recall one exam where I had to wire a motor control circuit from scratch, and then, immediately after, diagnose a fault intentionally introduced by the examiner. It’s a dynamic test, designed to push you beyond rote memorization. They want to see your problem-solving process in real-time, how you react under pressure, and your systematic approach to identifying and rectifying issues. Expect scenarios ranging from basic residential wiring to more complex industrial control panels, often incorporating programmable logic controllers (PLCs) or renewable energy components. My tip? Don’t just practice the perfect scenario; actively seek out resources that simulate common faults and ambiguous instructions. That’s where the real learning happens.

The Silent Rules: What Examiners Really Want

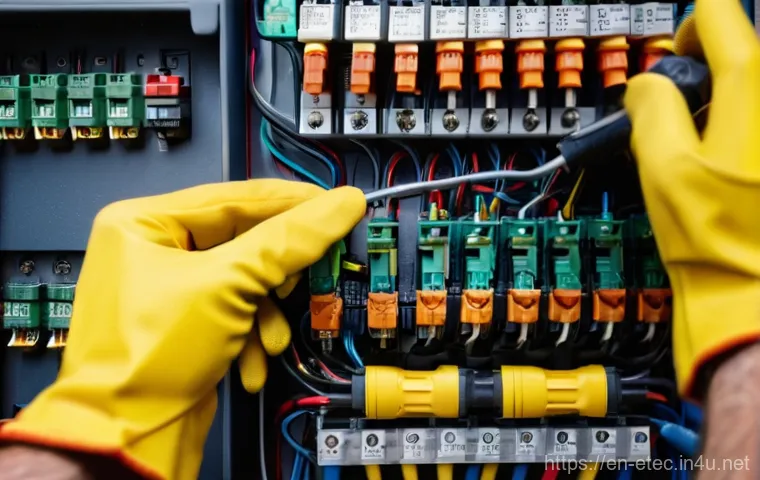

Beyond the official rubric, there are unspoken expectations. Neatness, for instance, isn’t just aesthetic; it reflects your attention to detail and professional work ethic. A clean, organized workspace and neatly terminated wires speak volumes. Safety is non-negotiable – personal protective equipment (PPE) usage, Lockout/Tagout procedures, and general awareness of electrical hazards are paramount. I once saw someone disqualified for not properly verifying a circuit was de-energized before beginning work, even though they technically knew how to do the task. It’s these fundamental habits that distinguish a competent professional from someone merely capable of following instructions. Develop these habits in your practice sessions, and they’ll become second nature during the exam.

Equipping for Success: Tools and Unwavering Safety Protocols

Before you even touch a wire, your toolkit and your mindset around safety are absolutely crucial. I remember my first major practical exam, and the sheer relief I felt knowing I had every essential tool precisely where I needed it. There’s nothing worse than fumbling for a specific wrench or stripping pliers under the clock. Beyond having the right tools, ensuring they’re in excellent condition is a game-changer. A worn-out screwdriver can strip a screw head, turning a simple task into a time-consuming headache. And let’s be honest, we’ve all been there, trying to make do with a subpar tool. But in an exam, that luxury doesn’t exist. My advice: invest in quality, maintain your tools diligently, and organize them systematically so you can grab what you need without a second thought. This proactive approach not only saves time but also builds a foundation of confidence.

Curating Your Exam-Ready Toolkit

When it comes to tools, it’s not about having the most expensive ones, but the right ones. For electrotechnology practicals, this typically includes a reliable multimeter, various screwdrivers (Phillips, flathead, insulated), wire strippers, crimpers, a continuity tester, a voltage detector, and sometimes specialized tools for conduits or motor controls. I personally swear by a good set of insulated hand tools – they’re not just a recommendation; they’re a lifeline. Think about the types of installations you’ll be doing and tailor your kit accordingly. Don’t forget consumables like electrical tape, wire nuts, and terminal blocks. A well-prepared kit demonstrates foresight and professionalism to your examiners, showing you’ve thought beyond just the theoretical knowledge. It’s like having your trusty sidekick ready for any challenge.

Safety First, Always: Non-Negotiable Practices

This isn’t just a checklist; it’s a deeply ingrained philosophy. Your practical exam is a critical evaluation of your ability to work safely in real-world conditions. Always, and I mean always, wear your personal protective equipment (PPE) – safety glasses, gloves, and appropriate footwear. I once hesitated to put on my safety glasses for a seemingly minor task during practice, and a tiny piece of wire flew right past my eye. Never again. Beyond PPE, understanding and implementing Lockout/Tagout (LOTO) procedures is paramount. This process ensures that circuits are completely de-energized and cannot be accidentally re-energized while you’re working on them. Verbalizing your safety checks during the exam, if permitted, can also demonstrate your awareness. Remember, making a mistake on a wiring diagram might cost you points, but a safety violation can cost you your career, or worse, your well-being. Examiners are looking for someone who prioritizes safety above all else, and you should too.

Flawless Execution: Mastering the Installation Process

Successfully installing electrical components is more than just connecting wires; it’s about precision, adherence to standards, and showcasing a methodical approach. I’ve learned that truly mastering installation means understanding the ‘why’ behind every step, not just the ‘how.’ For example, knowing why specific wire gauges are used for particular loads, or why a certain type of conduit is mandated in a given environment, elevates your work from merely functional to expertly engineered. I once watched a classmate rush through a conduit bending exercise, and while their bends technically worked, they were sloppy and didn’t meet the aesthetic or practical standards. The examiner noticed immediately. This taught me that attention to detail, even in seemingly minor aspects, profoundly impacts the overall assessment. Every bend, every termination, every label contributes to the bigger picture of a professional installation. This is where your deep understanding of electrical codes and best practices truly shines, transforming a simple task into a demonstration of your expertise.

Precision Wiring and Termination Techniques

When it comes to wiring, neatness and proper termination are non-negotiable. Loose connections are not just unsightly; they’re fire hazards and sources of inefficiency. From my own journey, I’ve found that taking an extra minute to ensure every wire is properly stripped, twisted, and secured makes all the difference. This includes using the correct terminal lugs, applying appropriate torque, and ensuring no stray strands are present. Color-coding, proper labeling, and organized wire runs within panels are also key indicators of a professional job. Examiners are scrutinizing your ability to create a reliable and maintainable system, not just a working one. Imagine someone else having to troubleshoot your work years down the line; your clear, precise wiring is their roadmap. Practice these techniques until they feel second nature, almost like an art form, because in many ways, they are.

Adhering to Electrical Codes and Standards

Electrical installations are governed by strict codes and standards – think NEC (National Electrical Code) in the US, or BS 7671 in the UK. These aren’t just guidelines; they are the law, designed for safety and efficiency. Your practical exam will implicitly (and sometimes explicitly) test your compliance with these codes. This means understanding grounding and bonding requirements, proper overcurrent protection, correct conduit fill ratios, and permissible wiring methods for different environments. I always recommend having a solid grasp of the relevant sections of your local electrical code. You don’t need to memorize the entire book, but knowing where to find critical information and understanding its application is vital. It shows you’re not just a technician, but a responsible professional. Staying updated on code changes is also a huge plus, showcasing your commitment to continuous learning in a dynamic field.

Troubleshooting Like a Maverick: Diagnosing and Remedying Faults

The true test of an electrotechnology professional isn’t just installing something correctly; it’s being able to fix it when it inevitably goes wrong. I’ve always found troubleshooting to be the most exhilarating and sometimes frustrating part of the job. It’s like being a detective, piecing together clues to uncover the culprit. In the practical exam, this skill is paramount. Examiners aren’t just looking for you to magically fix a problem; they want to see your systematic approach. Do you start with the simplest checks? Do you isolate sections of the circuit? Are you using your multimeter effectively? I distinctly remember a time during a practice session when I spent an hour chasing a complex fault, only to realize I hadn’t properly checked the power supply at the very beginning. It was a humbling lesson: always start with the basics and systematically eliminate variables. This approach not only saves time but prevents you from overcomplicating simple issues. Your ability to methodically diagnose and rectify faults showcases your analytical thinking and practical problem-solving capabilities, earning you major points on exam day.

Systematic Fault Isolation Strategies

When faced with a malfunctioning circuit, a scattered approach will only lead to frustration and wasted time. The key is to develop a systematic methodology. Start with a visual inspection – look for loose wires, burnt components, or tripped breakers. Then, move to voltage measurements at key points, comparing them to expected values. Is power reaching the control circuit? Is the output relay energizing? Use your multimeter to check continuity across fuses, switches, and motor windings. I’ve found that creating a mental or even a quick sketch of the circuit with test points helps immensely. Remember the ‘divide and conquer’ principle: isolate sections of the circuit to pinpoint where the fault lies. If a motor isn’t running, first check if the motor itself is receiving power. If not, backtrack to the contactor. If the contactor isn’t pulling in, check its coil voltage. This logical progression is what examiners are looking for – a clear, repeatable process that efficiently leads to the solution.

Effective Use of Diagnostic Tools

Your diagnostic tools are an extension of your senses. The multimeter is your best friend here, capable of measuring voltage, current, resistance, and sometimes continuity or capacitance. Knowing how to correctly set it for each measurement and interpret the readings is non-negotiable. I can’t stress enough the importance of regularly calibrating and checking your multimeter’s battery – a dead battery in the middle of a fault diagnosis is a nightmare! Beyond the multimeter, a good non-contact voltage tester can quickly identify energized conductors, and specialized tools like clamp meters for current measurement or thermal imagers for hot spots can be invaluable in certain situations. Practice using these tools until you’re completely comfortable with their functions and limitations. The more proficient you are with your diagnostic arsenal, the faster and more accurately you’ll be able to identify and fix problems, turning what could be a stressful exam moment into a confident demonstration of your expertise.

| Diagnostic Tool | Primary Function | Common Exam Use | Pro Tip |

|---|---|---|---|

| Digital Multimeter (DMM) | Measures voltage, current, resistance, continuity | Verifying power, checking component integrity, fault finding | Always select the correct range and function before testing. |

| Non-Contact Voltage Tester | Detects presence of AC voltage without direct contact | Quick safety check for live wires, identifying energized circuits | Useful for initial checks, but always confirm with a DMM. |

| Wire Strippers/Cutters | Prepares wires for termination | Ensuring clean, proper strip length for connections | Use the correct gauge slot to avoid damaging wire strands. |

| Insulated Screwdrivers | Securing terminals, general assembly/disassembly | Safety when working near live parts (though always de-energize!) | Essential for safety and preventing accidental short circuits. |

Operational Finesse: Refining Your System Control Skills

Getting a system wired correctly is one thing; making it hum with efficient, reliable operation is another. This is where your operational skills come into play, and it’s a critical part of any electrotechnology practical exam. It’s about more than just flipping a switch; it’s about understanding the sequence of operations, the interplay between different components, and how to safely and effectively control the system. From my own professional journey, I’ve found that even the most perfectly installed system can fail if its operation isn’t understood or executed properly. For instance, misinterpreting a control panel’s indicators or pressing buttons out of sequence can lead to unexpected shutdowns or, worse, damage to equipment. Examiners are keen to see that you can not only build these systems but also confidently bring them to life, monitor their performance, and interact with them intelligently. This demonstrates a complete understanding of the electrotechnological ecosystem, from conception to practical application, and shows you’re ready for the real-world demands of the job.

Interpreting Control Schematics and Diagrams

Before you even think about pressing a button, you need to understand the brain of the

Safe and Efficient System Startup and Shutdown

Bringing a system online or taking it offline safely is a sequence of precise steps that must be followed without fail. This isn’t just about routine; it’s about preventing accidents and protecting expensive equipment. For startup, this often involves pre-checks, energizing power in a specific order, verifying indicators, and then initiating the operational sequence. For shutdown, it’s usually the reverse, ensuring all loads are properly de-energized and safety mechanisms are engaged before isolating main power. I can’t emphasize enough how important it is to strictly adhere to established procedures. During one of my early certifications, I almost forgot to verify a motor’s rotation direction *before* fully integrating it into the system – a small oversight that could have led to significant operational issues. Examiners look for candidates who demonstrate discipline and an unwavering commitment to operational safety and best practices, showing you respect the power of the systems you’re working with.

Beyond the Bench: Cultivating Exam Day Mental Toughness

Let’s be real, practical exams can be nerve-wracking. The clock is ticking, the examiner is observing, and there’s that little voice in your head. But here’s the thing I’ve learned: mental preparation is just as vital as technical preparation. I’ve seen incredibly skilled individuals falter under pressure simply because they let anxiety get the best of them. It’s not just about knowing the material; it’s about being able to perform optimally when it counts. Managing your time effectively, staying calm when unexpected issues arise, and maintaining focus throughout the exam can make or break your performance. Remember, this isn’t just a test of your knowledge, but a test of your resilience and professionalism. Approaching the exam with a strategic mindset, not just a knowledgeable one, is the secret weapon that truly sets successful candidates apart. It’s about showing up fully present and confident, ready to tackle anything thrown your way.

Strategic Time Management Under Pressure

Time management in a practical exam is a unique beast. You’re not just answering questions; you’re performing tasks. Before you even start, take a moment to read through all instructions and mentally (or even briefly on scratch paper, if allowed) plan your approach. Allocate specific amounts of time to each major task, building in a buffer for unexpected snags. I personally learned the hard way that rushing through the initial planning phase to save time often backfires, leading to mistakes that take even longer to correct. If you encounter a stumbling block, don’t panic and immediately jump to the most complex solution. Take a deep breath, review your steps, and go back to basics. Sometimes, stepping away for 30 seconds to clear your head can make all the difference. Remember, the goal isn’t just to finish; it’s to finish accurately and safely. Pace yourself, stay organized, and trust your training.

Building Resilience and Battling Exam Nerves

Exam nerves are completely normal – anyone who says they don’t get them is probably fibbing! The trick isn’t to eliminate them, but to manage them. My go-to strategy involves deep breathing exercises before I even enter the room. Visualization can also be powerful: picture yourself successfully completing each task, calmly and confidently. If you hit a roadblock during the exam, instead of letting frustration mount, take a moment to re-read the specific instruction, check your tools, and systematically re-evaluate the problem. Don’t be afraid to ask for clarification if something truly isn’t clear (within the rules of the exam, of course). Most importantly, remind yourself of all the hard work and practice you’ve put in. You’ve earned this opportunity. Trust your skills, focus on one step at a time, and remember that a calm mind is your greatest asset in overcoming any practical challenge.

The Undeniable Edge of Hands-On Practice and Simulation

You know, there’s a massive difference between reading about how to wire a circuit and actually doing it. I mean, a monumental difference! I can’t stress this enough: genuine, hands-on practice is the absolute bedrock of success for any electrotechnology practical exam. Theory gives you the map, but practice teaches you how to drive. I’ve personally spent countless hours in workshops, meticulously wiring, unwiring, troubleshooting, and re-wiring circuits until the movements became second nature. It’s during these sessions that you build muscle memory, develop efficient work habits, and encounter the real-world quirks that textbooks just can’t convey. There’s a certain tactile confidence that only comes from physically manipulating tools and components, feeling the click of a relay, or seeing the flicker of a test light. Without this deep experiential learning, you’re essentially trying to win a marathon without ever having run a mile. This isn’t just about passing an exam; it’s about building the foundational competence that will serve you throughout your entire career.

Setting Up Your Personal Practice Hub

You don’t need a full-blown industrial lab to get quality practice. Many educational institutions offer open lab times, but if that’s not feasible, a modest home setup can be incredibly effective. I started with a simple breadboard, some common components, and a basic power supply. You can often source discarded components or buy starter kits online. Focus on simulating specific exam tasks: wiring a motor starter, setting up a basic lighting circuit, or integrating a simple sensor. The goal isn’t fancy; it’s functional. Create mock-ups of control panels, practice conduit bends, and repeatedly perform safe lockout/tagout procedures. The more realistic you make your practice environment, the better prepared you’ll be for the actual exam. Think of it as your personal sandbox where you can experiment, make mistakes without consequence, and refine your techniques until they are flawless.

Leveraging Simulation and Real-World Scenarios

Beyond physical practice, don’t underestimate the power of digital simulation tools. Software like PLC simulators or circuit design platforms can help you visualize complex systems and test logic before you ever touch a physical wire. While they don’t replace hands-on work, they’re fantastic for understanding system behavior and troubleshooting abstract faults. And when it comes to real-world scenarios, pay attention to every electrical installation you encounter. How is that light switch wired? What’s inside that control panel at your workplace? Every observation is a learning opportunity. If you have the chance, volunteer for small projects or assist experienced electricians. These informal experiences provide invaluable context and expose you to the nuances of actual installations and repairs. Combining structured practice with inquisitive observation and digital simulation creates a truly comprehensive preparation strategy, ensuring you’re ready for anything the practical exam throws your way.

글을 마치며

As we wrap up this comprehensive guide to acing your electrotechnology practical exam, I truly hope you feel a renewed sense of confidence and a clear roadmap ahead. Remember, this journey is about so much more than just a single test; it’s about solidifying your skills, building unwavering confidence, and proving to yourself – and future employers – that you’re not just capable, but truly exceptional in your craft. Every hour of practice, every diagram meticulously studied, every troubleshooting session under pressure, builds not just competence, but character. You’re not just preparing for an exam; you’re forging the foundation of a robust and rewarding career in electrotechnology. Keep that fire lit, keep learning with passion, and always strive for excellence because your dedication is what truly lights up your path in this dynamic field. I’ve seen firsthand how much impact genuine effort makes, and I’m absolutely confident you’ve got what it takes to shine.

알아두면 쓸모 있는 정보

1. Always double-check your connections. A single loose wire can lead to hours of troubleshooting, and in a real-world scenario, it can be a significant safety hazard. Develop a habit of visually inspecting every termination and ensuring proper torque.

2. Invest in quality tools, especially your multimeter and insulated hand tools. They are your most important companions, ensuring both accuracy and safety. Cheap tools often fail at critical moments, costing you time and potentially causing damage or injury.

3. Stay current with electrical codes and industry standards. These regulations evolve, and staying updated not only keeps you compliant but also ensures you’re practicing the safest and most efficient methods. Your knowledge here speaks volumes about your professionalism.

4. Don’t shy away from asking questions, even if they seem basic. In this field, clarity is paramount, and a quick question can prevent a major mistake. Even experienced professionals constantly seek clarification or a second opinion when facing complex challenges.

5. Network with other professionals. Joining industry forums, attending local trade events, or connecting on platforms like LinkedIn can open doors to mentorship, shared knowledge, and even future career opportunities. Learning from others’ experiences is an invaluable asset.

중요 사항 정리

To truly excel in your electrotechnology practical exam and beyond, remember these core pillars: prioritize unwavering safety protocols above all else – your well-being and that of others is non-negotiable and paramount. Adopt a systematic and methodical approach to every task, whether it’s installation, troubleshooting, or operation, as this demonstrates clear thinking, efficiency, and a deep understanding of the work. Cultivate mental toughness to navigate the pressures of examination day, staying calm and focused even when unexpected challenges arise, because your ability to perform under pressure is key. Most importantly, embrace relentless, hands-on practice; there’s simply no substitute for the tactile experience and muscle memory gained by physically working with tools and components repeatedly. This powerful combination of theoretical knowledge, practical skill, a safety-first mindset, and sheer dedication will not only help you pass with flying colors but will also firmly establish you as a highly competent, reliable, and respected professional in the dynamic world of electrotechnology. Keep that passion for problem-solving and innovation burning brightly!

Frequently Asked Questions (FAQ) 📖

Q: What’s the single biggest mistake you’ve seen people make during these electrotechnology practical exams, and how can I absolutely steer clear of it?

A: Oh, this is a fantastic question, and trust me, I’ve seen it play out more times than I can count. From my experience, the absolute biggest pitfall isn’t usually a lack of knowledge, but rather a combination of rushing and not thoroughly reading the instructions.

Picture this: you’re hyped up, you know your stuff, and you just want to get started. So, you skim the task, grab your tools, and dive in. But then, midway through, you realize you missed a crucial detail, like a specific wire gauge, a particular connection method, or a required safety check.

It’s like baking a cake without reading the part about the oven temperature! This can lead to costly errors, wasted time, and, worst of all, a failing grade, even if you theoretically know how to do the job.

My heartfelt advice? Before you touch a single wire, take a deep breath. Read the entire instruction set, not once, but twice.

Visualize each step. Make a mental checklist. Seriously, that extra five minutes of planning can save you hours of troubleshooting and a ton of anxiety.

Think of it as your secret weapon to staying calm, collected, and totally on point.

Q: Beyond just understanding the theory, what are the absolute ‘must-do’ practical skills I need to truly master to feel confident walking into the exam?

A: You’ve hit the nail on the head – theory is great, but practical exams are all about doing! What I’ve personally found invaluable is developing what I call “muscle memory” with the core skills.

It’s not just about knowing how to strip a wire or terminate a connection; it’s about doing it quickly, cleanly, and correctly every single time, almost without thinking.

This includes precise wire stripping without nicking the conductor, making solid, secure terminations – whether it’s twisting, crimping, or soldering – and consistently identifying components and symbols on a schematic diagram.

Think of it like learning to drive; you don’t just read the manual, you practice parking until it’s second nature. Troubleshooting is another huge one.

Examiners love throwing a curveball, a “fault” you need to find. So, get comfortable using your multimeter, reading continuity, checking voltage, and logically narrowing down potential issues.

I’d recommend setting up a small practice board at home, even if it’s just a basic circuit, and repeatedly performing these tasks until they feel like an extension of yourself.

Repetition builds confidence, and confidence crushes exam jitters.

Q: I’m really excited about a career in electrotechnology. Once I’ve successfully passed these exams, what are some of the most exciting or rapidly growing career paths or specializations that are really taking off right now?

A: This is where things get truly exciting! The world of electrotechnology is booming with innovation, and passing your practical exams is like getting a VIP pass to some incredibly dynamic fields.

Right now, what I’m seeing explode in terms of demand and sheer coolness factor are areas like renewable energy systems – think solar panel installation and maintenance, wind turbine technicians, and integrating battery storage solutions.

It’s a huge growth area, literally powering our future. Then there’s smart infrastructure and building automation. We’re talking about creating intelligent buildings that manage their own energy, lighting, and security – it’s a blend of electrical work and cutting-edge tech.

Another fascinating path is industrial automation, where you’ll be working with programmable logic controllers (PLCs) and robotics in manufacturing. And let’s not forget the rapidly expanding electric vehicle (EV) charging infrastructure.

Honestly, the skills you gain for these exams are foundational, but they open up so many doors. My advice? Follow what genuinely sparks your interest, because passion combined with your certified skills will lead you to a truly rewarding and future-proof career!